In high-temperature industrial applications—such as steelmaking, power generation, and petrochemical processing—the failure of refractory bricks can lead to costly downtime, safety hazards, and production inefficiencies. But how do you ensure your refractory solution is not just durable, but truly reliable?

According to industry data from the International Refractories Association (IRA), over 40% of unplanned furnace shutdowns in mid-sized steel plants are linked to premature refractory degradation. The root cause? Inconsistent raw material quality and lack of third-party validation. That’s where high-alumina content and international certifications become non-negotiable.

At Henan Ronghua Refractory Technology Co., Ltd., we use premium bauxite ore with an aluminum oxide (Al₂O₃) content exceeding 48%. This isn’t just a number—it translates into real-world performance:

“After switching to Ronghua’s high-purity bricks, our boiler efficiency improved by 7%, and maintenance costs dropped significantly.” — John Park, Plant Manager at a South Korean Power Station

These aren’t just compliance checkboxes—they’re proof of consistent manufacturing processes, rigorous testing protocols, and traceable quality control. For global buyers, this means reduced risk, fewer supply chain disruptions, and faster approval cycles when importing into EU, GCC, or North America markets.

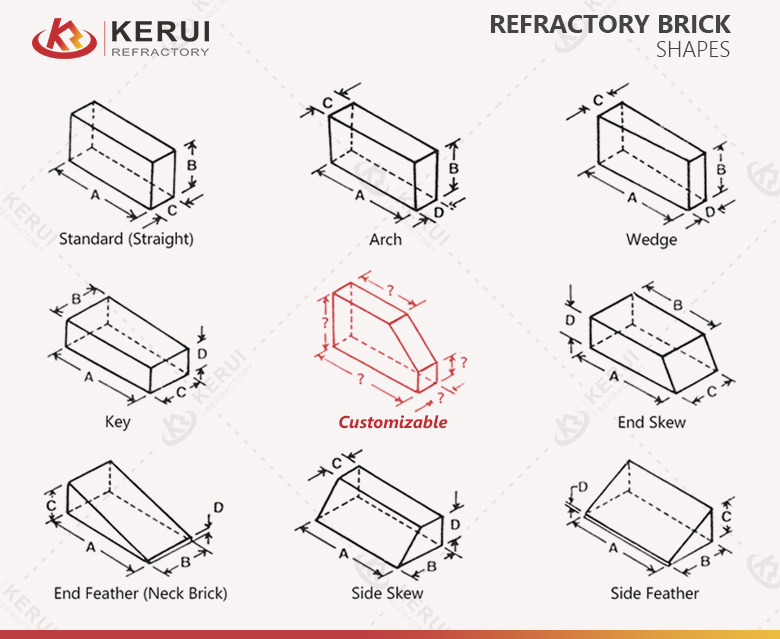

Our customized solutions have been deployed across:

| Industry | Application | Key Benefit |

|---|---|---|

| Steel Manufacturing | Ladle linings, tundish bricks | Reduced erosion rate by 30% |

| Power Generation | Boiler tubes, combustion chambers | Extended service life from 12 to 18 months |

| Petrochemical | Cracking furnaces, reformers | Improved thermal shock resistance during cyclic heating |

We don’t sell one-size-fits-all. Our process includes:

Get a free technical consultation tailored to your specific operating conditions—from material selection to installation support.

Download Technical Whitepaper →