Tier A (Critical hot zone)

Prioritize higher density, strong RUL, and corrosion resistance. Often 75–85% Al₂O₃ with tighter QC.

If you are sourcing refractory bricks for steel, cement, or other high‑temperature industries, you are not “just buying bricks.” You are buying uptime, stable kiln performance, and a measurable reduction in long-term maintenance risk. This guide helps you evaluate high‑alumina refractory bricks (Al₂O₃ > 75%) with ISO 9001 and CE compliance, so you can make a decision you can defend—in audits, in meetings, and on the production floor.

In steelmaking and cement lines, refractory failure rarely looks like a “material issue” at first. It shows up as temperature drift, hot spots, unexpected shutdowns, or inconsistent product quality. That is why procurement decision-makers typically care about three outcomes:

When you frame your goal this way, the selection criteria become much clearer: chemistry, density, strength, thermal stability, and certified quality management—rather than marketing promises.

For alumina refractory bricks, performance is not a single number. You should check a small set of indicators that correlate strongly with kiln reliability. Below is a practical benchmark table you can use for initial screening (final values depend on grade and firing profile).

| Parameter | Recommended for Al₂O₃ > 75% Bricks | Why It Matters in Real Kilns |

|---|---|---|

| Al₂O₃ content | > 75% (often 75–85% for common high‑alumina grades) | Improves slag resistance and refractoriness; supports longer campaigns. |

| Bulk density | 2.45–2.80 g/cm³ | Higher density usually means lower porosity and reduced penetration by slag/alkalis. |

| Apparent porosity | ≤ 18–22% | Lower porosity reduces chemical attack and thermal cycling damage. |

| Cold crushing strength (CCS) | ≥ 60–100 MPa | Better mechanical integrity during installation and service vibration/load. |

| Refractoriness under load (RUL) | ≥ 1450–1550°C (grade dependent) | Helps prevent creep/deformation in hot zones. |

| Thermal shock resistance | Stable after 20–30 cycles (typical lab cycle tests) | Reduces spalling during frequent heat-up/cool-down or operational fluctuations. |

If your supplier cannot provide a consistent test report set (and explain the test standards), treat that as a procurement risk—especially for large-volume kiln lining projects.

In many kiln and furnace zones, the enemy is not only heat—it is chemical attack from slags, alkalis, and dust infiltration. Higher alumina content typically provides stronger resistance to erosion and corrosion than lower-grade fireclay bricks.

As a working reference: compared with bricks in the ~50–60% Al₂O₃ range, 75%+ alumina bricks often show:

Reduced open porosity helps slow infiltration, delaying structural weakening.

Higher alumina phases generally sustain load better in high-temperature zones.

Fewer “early surprises” translate into smoother maintenance planning.

The practical procurement takeaway: if your operation is suffering from frequent patching or premature wear, moving up to a properly engineered 75%+ alumina grade is often a faster win than negotiating a small discount on a lower grade.

You already know certifications are important—but the value is clearest when you connect them to your daily procurement risks.

ISO 9001 is less about a single test result and more about repeatability: raw material control, traceability, process parameters, inspection checkpoints, and corrective actions. For you, this can mean fewer batch-to-batch deviations in density, strength, and dimensions—exactly the factors that cause installation headaches and early wear.

CE marking is relevant when supplying into regulated markets or projects that demand documented conformity. It supports smoother project approval, reduces compliance friction, and strengthens confidence when your end client or EPC requires formal documentation.

The procurement advantage is simple: certifications turn quality from a “promise” into a managed system. Not just refractory—reliability.

“After switching critical hot-zone areas to 75%+ alumina bricks and tightening incoming inspection standards, our kiln lining campaign extended by about 30%. The biggest gain was fewer unplanned stoppages—maintenance became predictable again.”

Your result will depend on installation quality, operating discipline, and—most importantly—whether the grade truly matches your slag chemistry and thermal cycling profile. But the case above reflects what many plants see: the biggest ROI comes from avoided downtime, not from the brick itself.

A common mistake in refractory procurement is choosing the highest specification everywhere. That can inflate costs without improving performance. What you want is zone-by-zone matching.

Once you clarify those points, you can define sensible grade tiers. A typical approach is:

Prioritize higher density, strong RUL, and corrosion resistance. Often 75–85% Al₂O₃ with tighter QC.

Balance performance and cost. Focus on consistent batch properties and thermal shock behavior.

Avoid unnecessary over-spec. Reliability still matters, but corrosion/creep demands may be lower.

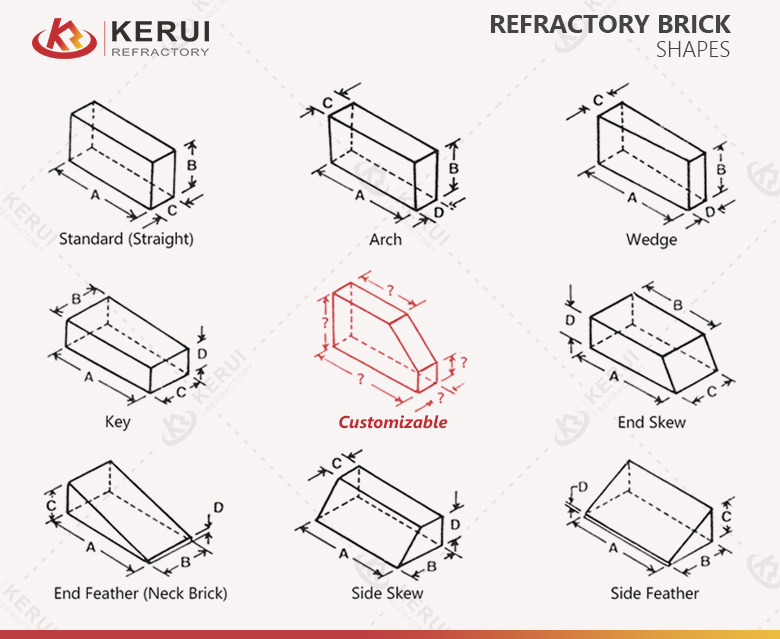

This is where customization becomes valuable: multiple grades, consistent dimensions, controlled tolerances, and clear documentation. Let every brick become the foundation of your efficient production—not just refractory, but dependable.

Share your operating temperature range, slag/alkali characteristics, and target lining zone. We will recommend a matching grade set and provide documentation aligned with ISO 9001 and CE expectations—so your procurement decision is clear, defensible, and practical.

Request a Quote for ISO9001 & CE Certified High‑Alumina (Al₂O₃ > 75%) Refractory BricksQuestion for you: which zone is failing first in your kiln or furnace—the hot face, the transition area, or the high-abrasion section? Leave a comment with your zone and temperature, and you’ll get a practical grade-matching suggestion.