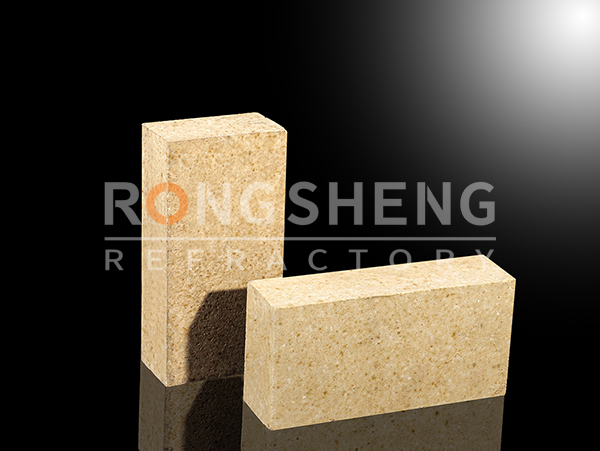

In the realm of industrial applications, the demand for high-performance materials is ever-increasing. Aluminum spinel refractory bricks represent a significant advancement in refractory technology, designed to withstand extreme conditions while enhancing efficiency and durability.

.jpg)

These refractory bricks are known for their superior thermal stability and resistance to slag erosion, making them ideal for environments where excessive heat and corrosive materials are prevalent. With an alumina content of over 70%, aluminum spinel bricks demonstrate impressive mechanical strength and longevity.

The durability of aluminum spinel bricks is critical for minimizing downtime in industrial processes. Their composition ensures a longer service life, reducing the frequency of repairs and replacements that can hinder production.

Aluminum spinel refractory bricks find utility in various sectors, including metallurgy, cement production, and petrochemical industries. Their ability to perform under high temperatures, often exceeding 1750°C, positions them as a leading choice among refractory materials.

With their robust features and extensive application range, aluminum spinel refractory bricks are indispensable in modern industry. Businesses aiming for efficiency and durability in high-temperature environments should consider these high-performance materials to gain a competitive edge.